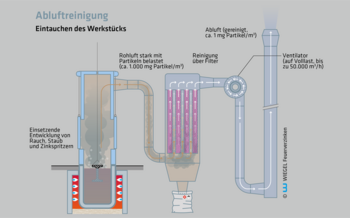

The animation shows the schematic sequence of hot-dip galvanizing and the associated air purification system:

3. Immersion of the workpiece

As the workpiece begins to be immersed in the zinc bath a lot of smoke and dust are produced and minute particles of metallic zinc can also splash up. The exhaust air over the zinc bath contains up to 1 g of particles per cubic metre. The exhaust system is running at full speed. The exhaust air is sucked through the filter at a very high volume flow rate.

![[English] Das Zinkbad im unbeladenen Zustand: Staub- und Rauchentwicklung über dem Zinkbad sind gering.](/fileadmin/_processed_/e/4/csm_wgl_Umwelt_Verzinkungslinie_1_Leerlauf_9a981c502e.png)

![[English] Zum Abziehen der Oxide von der Zinkbadoberfläche und anderer manueller Arbeitsschritte müssen die Seitenwände der Einhausung hochgefahren werden. Durch den starken Saugzug gelangen keinerlei Verunreinigungen in die Außenluft.](/fileadmin/_processed_/1/1/csm_wgl_Umwelt_Verzinkungslinie_5_Ausziehen_e0f6840083.png)